Lean Phase Pneumatic Conveying Systems are machinery to assist to move material such as powder, and. Pieces by way of pipes using air. They are great where things need to be moved and moved quickly, like in a factory. Let’s find out more about these systems and how they operate, the advantages, design features, improvements and how to get the best out of them, plus some problems and their solutions.

Lean Phase Pneumatic Conveying Systems just think of them as being big vacuum cleaners. They inhale the material, whether it is powder or pellets, and blow it through pipes to its destination. It makes factories better and faster by moving things around in an easy way.

There are lots of great things about using these lean phase pneumatic conveying system by JYSR in factories. One great feature is that they are able to get material through incredibly quickly and save time. They can also transport products a good distance, a key benefit in large factories. And they are safe, they require relatively little manual labor, meaning the potential for accidents is reduced.

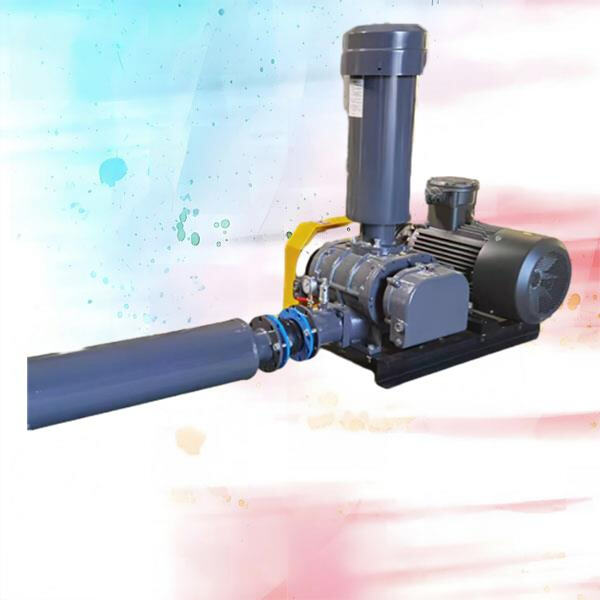

The Lean Phase Pneumatic Conveying system comprises of a number of key components which all play their part in the process. First, there is a pump, which draws the materials through the pipes. Then an air compressor assists in moving the materials down. There are also filters to clean the air and separators to help sort the material from the air that comes out of these things. All of these parts assist materials in getting where they need to go.

In order to have your JYSR lean phase conveying system function well, follow these tips: When you need to unclog, keep the pipes clean and clear so that materials can flow cleanly, with a clear passage at all times. Regulate the air pressure properly so materials do not become stuck or move too quickly. Routine maintenance, such as looking for leaks or broken parts, can also help everything run efficiently.

Now and then Lean Phase Pneumatic Conveying Systems go wrong. Material getting stuck in the pipes is one common problem that can slow the process. The solution to this one is cleaning and maintaining the JYSR lean phase conveying system frequently. Another issue is materials becoming damaged during moving. One way to help fend off this, however, is by having the right tools and keeping a close eye on the system.

employees, from director to the worker, service providers who provide most professional service. Before leaving Lean phase pneumatic conveying system facility, all products are checked against strict set of testing. If there are any problems with the quality of the product, it will be replaced within year. Video tutorials for troubleshooting within 24 hours. can go the project site detect problems with the product in less than 48 hours and provide immediate solutions.

Three-blade Roots Blower more quiet and has less vibration when compared to two-blade Roots Blower. The castings made with resin sand technology. Additionally, impeller developed following the involute theory, which then replicated a computer that fully ensures meshing characteristics of the involute, and increases effectiveness. intake and exhaust portsspiral shape and are equipped with a muffler, so that intake and Lean phase pneumatic conveying systempulses smooth and quiet, with a low level vibration and sound is extremely low. gear for the fan is constructed of 20CrmnTi. It has been ground and carburized with an accuracy of five. The tooth's surface is a higher wear resistance and reduces noise from the gear.

Shandong Jianyu Heavy Industry Co. Ltd. Roots blowers root blowers are suitable melt-blown fabric, aquaculture, sewage treatment, pneumatic transport, special gases, desulfurization, dust removal, petrochemicals power cement and other industries. Roots blowers are manufactured in the US produced and offer the issue strength. company is a multi-functional business which combines development, research manufacturing. most popular product of the Lean phase pneumatic conveying systemis three-blade Roots blower is optimized designed by absorbing domestic and foreign Roots blower designs. There more than ten models, and over 100 different specifications. It is small in dimensions, big in flow, low in noise, and easy to operate. machine is quiet, there almost no vibration throughout the machine.

(1)More efficientTransmission lubrication system coordination structure are distinct can reduce losses.(2)Longer life primary Lean phase pneumatic conveying systemimported, and unique design of lubrication system helps the fan function easily, safely efficiently with a low rate of failure longer run time.(3) energy efficiency and protection of the environmentThe design of the unique sealing system makes the output air cleaner. The structure's patented noise reduction design makes the equipment less noisy and also reduces energy consumption.

Copyright © Shandong Jianyu Heavy Industry Co., Ltd. All Rights Reserved | Blog | Privacy Policy