Curious where the powder your favorite candy, milk & even face powder get to place that it hits a store? This redirection of these materials is performed with an exclusive system that is called as pneumatic conveying systems. We usually refer to these systems as vacuum cleaner kind, but rather than getting rid of dust, they relocate powders! And lean phase conveying is one such system. The conveying system start up observed that it sounds like the perfect smart, affordable transport solution for all sorts of materials --powders and granules.

Well, what is exactly Powder Transfer? Could you hurt more with exit followed by import, or only moving material in one place to another. For example, it could be moving powder from a store room to the production line in a factory. Intended for rapid and efficient handling of powders and other dry materials created by Macawber Eng. with our lean phase pneumatic conveyors. A powerful stream of air pushes them through a pipe or tube. Similar to sipping a liquid through a straw. This low-phase pneumatic conveying system of JYSR ensures high efficiency, and consumes less air compression to transport materials thus making it an energy as well as money saver tool for the companies using it.

Among them smooth and fast material transfer is crucial in production factories for the efficient low cost of materials for production process. At this lean time period, pneumatic conveying the systems work in a gracious manner with heavy-role. These are critical in feeding the input required to the process in a consistent and continuous manner that nobody again will be waiting in line. This would be like if you wanted to pour water in a cup. But instead of pouring freely, the water was flapping around everywhere and missing the spot you wanted to hit! That would be messy! JYSR lean phase system is designed to deliver consistent flow of materials making wear, interruptions and inefficiencies due to variability raw material to the process almost non-existent. This pneumatic conveying system makes the products faster and less error-prone.

The moment you put confectioners in a bag, the whole family starts clinging to that inner plastic! That’s an example of waste! There is also a Wastage instant when transferring of powdered items to the other site. Advanced lean phase pneumatic technology allows these materials to be managed more efficiently in that they optimize consumption so, when you need this material to transport a batch of product from one area to other (for instance from a silo or extruder combination), the maximum amount in order to handle as much as possible every minute while reducing waste. JYSR system can increase materials accuracy, reduce waste and deliver material by Very High Efficiency. This is because with less waste, it means more materials are used (and we all know that using more material to make a product is better for the environment and business).

Positive Pressure Pneumatic Conveying and Bulk Material Transport Positive pressure conveying obviously has the basic advantage of offering great flexibility of routes between processing stations.

Bulk Material —Bulk Material Handling is the process of transporting, storing and controlling free flowing materials which can be in solid form (fine or large particles) such as powders, granules and other loose material. This material conveying system type of work is an ideal application for a lean phase conveying system. People who can shed a few kilos here and there would factor into the weight, You know light car means less fuel consumption which is good for guys (nature) and you wallet. They are simpler to keep up as properly, leading to savings for firms on repairs. Furthermore, these systems are designed to be user-cooperative. Because lean phase conveying system are suitable for a wide-ranging of powders and dry materials it becomes an excellent operation to all kinds of bulk material handling due to its feature.

(1)More efficientunique design precise Lean phase pneumatic conveying systemof transmission and lubrication systems reduce various losses dramatically improve the efficiency of the machine.(2)Longer life key components are imported. Additionally, the unique design of lubrication system helps fan work effortlessly, safely and effectively with low failure rates a longer service life.Energy conservation environmental protectionThe unique sealing system design allows the output air to be cleaner. The innovative noise reduction design reduces the noise of the device and helps reduce energy consumption.

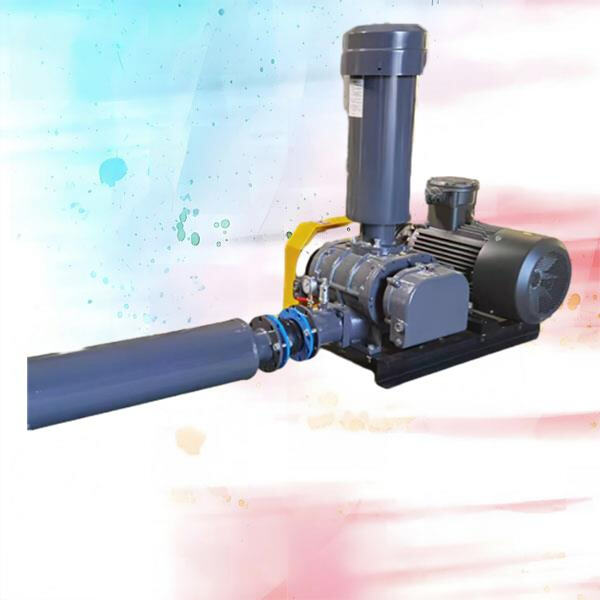

Shandong Jianyu Heavy Industry Co. Ltd. Roots blowers root blowers are suitable melt-blown fabric, aquaculture, sewage treatment, pneumatic transport, special gases, desulfurization, dust removal, petrochemicals power cement and other industries. Roots blowers are manufactured in the US produced and offer the issue strength. company is a multi-functional business which combines development, research manufacturing. most popular product of the Lean phase pneumatic conveying systemis three-blade Roots blower is optimized designed by absorbing domestic and foreign Roots blower designs. There more than ten models, and over 100 different specifications. It is small in dimensions, big in flow, low in noise, and easy to operate. machine is quiet, there almost no vibration throughout the machine.

From director to workers, they all Lean phase pneumatic conveying systemproviders. They provide customers with highest quality and professional service. Before leaving factory, all products are examined meet a strict level of testing. If there is any problems with quality of product, it will be replaced within year. Video tutorials for troubleshooting within 24 hours. is able to visit project website to spot any issues within 48 hours, and provide prompt solutions.

three-blade Roots Blower is quieter has lower vibration compared to the two-blade Roots Blower. castings are cast with resin sand, and the impeller designed strictly in accordance with theory of involute, and then modelled in a computer that is a complete guarantee of the meshing Lean phase pneumatic conveying systemof involute, and increases efficiency. exhaust intake ports have a spiral design and come with a muffler. This ensures that the intake and exhaust vibrations soft, the vibration is small and the noise low. The fan gear has been constructed of 20CrmnTi and has been carburized, and then ground to level 5 precision. tooth's surface has more resistance to wear and lowers the sound of the gear.

Copyright © Shandong Jianyu Heavy Industry Co., Ltd. All Rights Reserved | Blog | Privacy Policy