lean phase pneumatic conveying system is one such method used to transfer the bulk materials such as powders, pellets and granules from one process part or place of the plant to another. This process will still be under other material conveying which mostly is the dilute phase conveying. They retrieve a lot more raw material and during the time that these resources are still useable so that the factories have to create far far less. It offers excellent security, particularly to companies that use higher-quality materials and want to make certain their goods are both safe and efficacious.

A company that has to move a lot of material each day can save money with dense phase conveying. Not only so, it is also able to carry large amounts of building supplies without any damage up to the long way. This is done by very low speed air but on the high pressure side. Little modification is only required to protect the materials such that they undergo a journey without being damaged and losing their fundamental characteristics.

Dense phase conveying began to be used in the handling of such material even more recently, an example being in food processing, chemical manufacturing and production with plastics. It is a perfectly rational way of deploying otherwise fragile materials which will be broken if one tries too hard. Dense phase conveying is a simple solution for such industries as it helps keep their products well-maintained thus, allowing them to maintain high standards and cater every customer satisfaction.

Materials can be moved around slowly and at high cost in many businesses. This can be a much faster, less expensive method for businesses to use when they perform dense phase conveyance. They are then able to move their items anywhere they need to, without the use of time and resources. This in turn reduces the requirement of handlers on material handling too. The systems based on gas-solid fluidized bed are simple to install, in terms of operation; this dense phase conveying covers these types of systems. These can be operated with limited training or no specialised skills required from the worker side.

Apart from faster conveyance, dense phase provides the means to avoid material degradation that ensures the integrity of the substance conveyed. Since it is a relatively gentle procedure, the substances do not suffer much damage and are of good quality during the entire process. This all amounts to higher-quality products at a reduced waste, something that should be good news for any factory looking to maximize their production output. Also, options which allow the dense phase conveying system to be configured for the material handling needs of diverse materials. So they can process many items with different attributes.

As one of the largest innovators in material handling, JYSR has created different types of dense phase conveyor to suit all kinds of customers. No matter the application (food, pharmaceutical, industrial), JYSR makes its systems capable of moving loads as quickly as possible. This eventually results in smooth transit, complimenting the production output quality. JYSR focuses on providing its clients with optimal material-handling solutions to help them achieve their operational requirements.

Every employee, from director all way to the worker are service providers who Dense phase pneumatic conveyinghighest quality and professional service. products undergo a rigorous, standardized inspection before leave the factory. If there issues with the product's quality, it will be replaced within year. Video guidance for debugging within 24 hours, you can visit the site of the project to identify any issues within 48 hours, and provide prompt solutions.

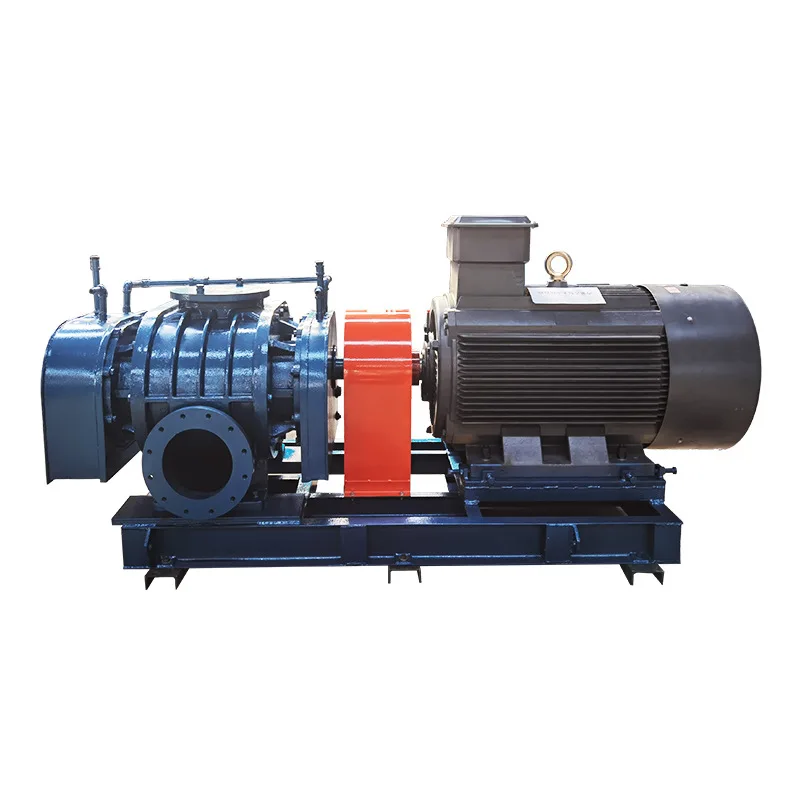

Three-blade Roots Blower more quiet and has less vibration compared the two-blade Dense phase pneumatic conveyingBlower. The castings made with resin sand technology, the impeller is constructed following the theory of involute and then simulated on a computer, which completely ensures the meshing properties the involute as well as increases efficiency. The intake and exit ports are spiral-shaped, and include muffler to reduce the noise vibration. fan gear has been constructed of 20CrmnTi and has been carburized later ground to a level 5 precision. tooth surface more wear-resistant and could drastically reduce the noise of gears.

(1)More efficientCoordination of lubrication transmission systems as well as Dense phase pneumatic conveyingare unique can reduce losses.(2)Longer lifefan functions easily, efficiently safely using imported components and unique design of system of lubrication. has a low rate of failure as well as longer time-to-life.(3) Energy efficiency protection of environmentThe innovative sealing system design allows the output air to be cleaner. The structure's patented noise reduction design reduces the noise of the device; and effectively reduces energy consumption.

Shandong Jianyu Heavy Industry Co., Ltd. Blowers roots and root are suitable melt-blown fabric, sewage treatment, aquaculture, pneumatic transportation, special gases, desulfurization and dust removal, petrochemicals, power cement, and many other industries. These Roots blowers domestically produced offer the issue strength. company is a leader in technical manufacturing and development capabilities, is business that integrates manufacturing, development, research and sales. three-blade Roots Blower, the main product of company has been designed and optimized using international and domestic Roots blower experiences. There over 10 models and more than 100 Dense phase pneumatic conveying. It easy to use, tiny but has a significant flow rate, and has a low noise. There is no noise, and almost no sound throughout the machine.

Copyright © Shandong Jianyu Heavy Industry Co., Ltd. All Rights Reserved | Blog | Privacy Policy