तेज चक्रीय पेसरहरूले चक्रीय पेसर प्रोद्योगिकीको क्षेत्रमा सबैभन्दा बढ़िसकेको छ। बढी तेजीमा चल्ने पेसरहरूसँग जोडिएको छ, जसले फेरिने पेसर सामग्रीहरूलाई बहुत चाँडो गतिमा फेल्न सक्छ। जसले अन्तर्गत उद्योगीहरूलाई बढी उत्पादन दर प्राप्त गराउँछ, जसले रोजगार छ! यदि कम्पनीहरूले त्वरितरीतेमा चीजहरू बनाउन सक्छन्, त्यसले वे आदेशहरूलाई समयमा पूरा गर्न सक्छन् र संभावित रूपमा पैसा बचाउन सक्छन्।

रोटारी फीडर तकनीकमा सबैभन्दा महत्वपूर्ण परिवर्तनहरूपैकी एक छ, कि अहिले कंप्युटरले बोस रहेको छ र मशीनहरू कसरी चलाउने हो भनेर निर्धारण गर्दछ। फीडरहरू कंप्युटर नियन्त्रणहरूसँग संगत छन्, जसले तिनीहरूलाई अधिकांश वेला आफूतिमी चलाउन प्रोग्राम गर्न सकिन्छ। यो एउटा महत्वपूर्ण प्रगति हो, जसले पूर्ण प्रक्रियालाई कर्मचारीहरू लागि सुरक्षित बनाउँदछ र तिनीहरूलाई अन्य कामहरू प्रदर्शन गर्न मद्दत गर्दछ।

यसले रोटारी फीडरलाई विविध उद्योगहरूमा उच्च महत्वका यन्त्रहरू बनाउँछ, किनकि तिनीहरूले माटीहरूको गतिप्रदानलाई मशीनहरूद्वारा सजिलै र तेजै गर्न सक्दछ। यदि roto feeder , भन्दा बिना हुन्थ्यो, त्यसपछि तिनीहरूलाई खानाको लागि आफ्नै खर्च गर्न पर्छ र त्यसमा धेरै समय खर्च गर्न पर्छ। JYSR ले रोटारी फीडर निर्माण कम्पनीहरूमध्ये एक बढ्दो मानिन्छ र त्योको उत्पादनहरू विविध सामग्रीहरू प्रबंधन गर्न विशेष रूपमा बनाइएका छन्। यो पाउडर, पेलेट, र अझै पनि तरलहरूको रूपमा हुन सक्छ।

रोटरी फीडरहरू विशेष रूपमा सहायक हुन सक्छ किनकि तीहरूले विभिन्न प्रकारको रेंज प्रदान गर्दछ जसले JYSRलाई प्रत्येक ग्राहकको व्यक्तिगत आवश्यकताहरूको अनुसार अपनो पेशगी बनाउन मद्दत गर्दछ। तीहरूले साधारण रोटरी फीडरहरू पेस्किङको लागि र विशेष ठूलाइ डिझाइन गरिएका रोटरी फीडरहरू पेश गर्दछन् जसले विशिष्ट कामहरूमा प्रयोग गरिन्छ। यसको अर्थ हो कि यदि कुनै कम्पनीले कुनै पदार्थ हैन्डलिङ्ग कामहरू संभाल्नु पर्छ, त्यसैले ती प्रायः JYSRको रोटरी फीडर प्रयोग गर्न सक्छ जसले फलन पूरा गर्न सहायता गर्दछ।

JYSRको रचनात्मक फीडरहरूले एउटा महत्वपूर्ण फाइदा प्रदान गर्दछ किनकि तीहरूले अपशिष्टको मात्रा कम गर्न डिझाइन गरिएको छ। अपशिष्टलाई रोक्न सधैँ महत्वपूर्ण छ, खासगरी ती पद्धतिहरूको लागि जसले खर्ची भएका पदार्थहरू वा प्राप्त गर्न मुश्किल छ। JYSRले अपशिष्ट बचाउन द्वारा त्यसका ग्राहकहरूलाई पैसा बचाउन र त्योहरूको कुल खर्च घटाउन मद्दत गर्दछ, जसले कुनै पनि व्यवसायलाई हरूदार अवस्था प्रदान गर्दछ।

र JYSRले किन एक श्रेष्ठहरूमध्ये एकको नाम प्रतिष्ठा राख्दो roots rotary lobe blower manual सबैभन्दा नविन प्रोद्योगिकीको उपयोग गरेर र मात्र सुचालक सामग्रीहरूको उपयोग गरेर हामीले खाद्य पेसरहरूलाई वर्षहरूको लागि निर्विघटन नै सेवामा अनुशासित बनाउने गर्छ। गुणस्तरमा ध्यान दिइएको छ, JYSR खाद्य पेसरहरूले ठूलो समयको सेवाजीवन छ, जसले उद्योग 4.0 का सिद्धान्तहरूबाट बनाइएको स्मार्ट स्वचालनमा निवेश गर्दा कम्पनीहरूलाई भरोसा दिन गर्छ।

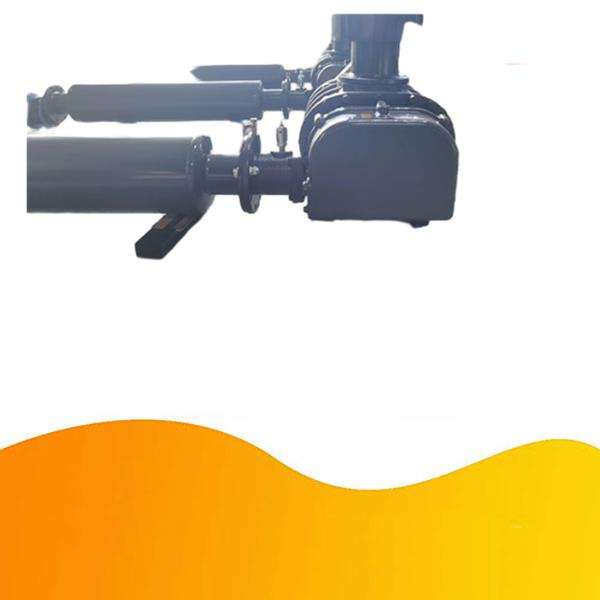

शान्दोंग जियान्यु हेभी इन्डस्ट्री को., लि.को रूट्स ब्लोअरहरू मेल्ट-ब्लोन कपडा, सीवेज उपचार, मत्स्य पालन, वायुमार्ग वाहन व्यवस्था, विशेष ग्याँसहरू, डिसल्फराइजेसन, धूल हटाउने, पेट्रोरसायन, बिजुली, सिमेन्ट र अन्य धेरै उद्योगहरूका लागि उपयुक्त छन्। रूट्स ब्लोअरहरू स्थानीय रूपमा निर्मित छन् र घूर्णन फीडर निर्माताहरूको लागि शक्तिशाली समस्याको समाधान प्रदान गर्छन्। कम्पनी प्रविधि उत्पादन र विकासक्षमतामा नेतृत्व गर्ने क्षेत्रमा अग्रणी छ। यो उत्पादन, विकास, अनुसन्धान र बिक्री समावेश गर्ने एकीकृत उद्यम हो। कम्पनीको शीर्ष उत्पादन तीन-पाखुरा रूट्स ब्लोअर हो, जुन घरेलु र विदेशी रूट्स ब्लोअरको डिजाइन अनुभवहरूलाई आत्मसात् गरेर अनुकूलित र विकसित गरिएको छ। यसमा दसभन्दा बढी मोडलहरू र सयभन्दा बढी विशिष्टताहरू उपलब्ध छन्। यो सानो आकारको छ, तर प्रवाह धेरै ठूलो छ, शोर धेरै कम छ र प्रयोग गर्न सजिलो छ। मेसिन शान्त छ, पूरै मेसिनमा लगभग कुनै आवाज नै सुनिँदैन।

(1)अधिक कुशल पारेको संचरण र स्नेहन प्रणालीको समन्वय र संरचना विशिष्ट छ र यसले हानि घटाउन सक्छ। (2)लामो जीवन मुख्य घटकहरू आयातित छन् र स्नेहनको विशिष्ट डिजाइनले फ्यानलाई कम खराबी दर, लामो समयसम्म चल्ने अवस्थामा सजिलै, सुरक्षित र प्रभावकारी ढंगले चलाउन अनुमति दिन्छ। ऊर्जा संरक्षण र वातावरण संरक्षण विशिष्ट सील प्रणाली डिजाइनले ग्यारेन्टी दिन्छ कि वायु निकासी बढी सफा हुन्छ। वैज्ञानिक शोर घटाउने संरचनात्मक डिजाइनले उपकरणलाई कम शोर उत्पादन गर्ने बनाउँछ; प्रभावकारी ढंगले ऊर्जा प्रयोग घटाउँछ।

निर्देशकदेखि कर्मचारीसम्म, उनीहरू ग्राहकहरूलाई सबैभन्दा ईमानदार र विश्वसनीय सेवाहरू प्रदान गर्ने सेवा प्रदायकहरू हुन्। कारखानाबाट बाहिर जानुअघि प्रत्येक उत्पादनमा कडा परीक्षण मापदण्ड लागू गरिन्छ। यदि घूर्णन फीडर निर्माताहरूले उत्पादनको गुणस्तरमा कुनै समस्या पाएमा, त्यो एक वर्षभित्र प्रतिस्थापन गरिनेछ। २४ घण्टाभित्र भिडियो सहयोगमा डिबगिङ गरिनेछ। तपाईं ४८ घण्टाभित्र परियोजनाको स्थलमा जाएर उत्पादनका समस्याहरू पहिचान गर्न सक्नुहुन्छ र छिटो समाधान प्रदान गर्न सक्नुहुन्छ।

तीन-पंखुडी रूट्स ब्लोअर दुई-पंखुडी रूट्स ब्लोअरको तुलनामा धेरै शान्त हुन्छ र कम कम्पन उत्पन्न गर्छ। ढलाइहरू रेजिन राम्रो बालुवाको प्रविधिप्रयोग गरी ढलिएका हुन्छन् र इम्पेलर कम्प्युटरद्वारा अनुकरण गरिएको इन्भोल्युट सिद्धान्त अनुसार निर्माण गरिएको हुन्छ। यसले इन्भोल्युटको जोडाउने विशेषताहरूलाई अधिकतम बनाउँछ र दक्षता पनि बढाउँछ। निकास र घूर्णन फिडर निर्माताहरूका लागि पोर्टहरू सर्पिल आकारमा व्यवस्थित गरिएका हुन्छन् र मफलरसँगै आउँछन्। यसले आवश्यकता र निकासको कम्पनलाई मृदु बनाउँछ, साथै कम्पन र शोर दुवै कम राख्छ। फ्यान गियर २०CrMnTiबाट बनाइएको हुन्छ जसलाई कार्बुराइज गरिएको छ र पछि ५ डिग्रीको सटीकतामा ग्राइण्ड गरिएको छ। दाँतको सतह अधिक घर्षण प्रतिरोधी हुन्छ र गियरको आवाजलाई उल्लेखनीय रूपमा कम गर्न सक्छ।

कॉपीराइट © शांगडोन्ग जियान्यू हेभी इंडस्ट्री को., ल्ट्ड. सबै हक राखिएका छन् | ब्लग∙गोपनीयता नीति