The Twin Lobe Rotary Air Blower is a device which transfers air or gas to the designated area. Twin lobe because it has two parts, called lobes which are turning in opposite directions. As these lobes rotate, they generate a low-pressure area that sucks in air from the outside and forces it out with great pressure. That is what makes this machine so good at pushing air, and doing it quickly.

This type of blower is widely used in a variety industries and applications. It is fundamental in, for instance, the purification of wastewater and material transport; HVAC systems (heating or cooling) appear across all these examples. It is additionally used in the manufacture of many things such as cement, sugar and chemicals. The twin lobe rotary air blower is an ideal tool for a wide variety of jobs, as it has incredible versatility due to the fact that it works so well and grants such high power output.

Those who use HVAC know how necessary it is to maintain a warm and cool environment by consistently delivering cold or hot air through effective ventilation. Increased energy bills: A poorly functioning HVAC system may result in your heating unit or cooling unit needing to work harder, which can cause higher electricity costs for you. The twin lobe rotary air blower based units help immensely in this aspect.

Doing this can help get the most out of your HVAC system by making it move more air and save you in energy costs from heating/cooling loads. It is a solid and dependable machine that you may use to have increased efficiency in your house or office with respect to VS HVAC technology. Thus, it is highly recommended to install or simply replace the twin lobe rotary air blower for a better airflow in your home or at all work sites. This will help you maintain a healthier atmosphere where the air is fresher.

We should all become efficient in the way we work, regardless of our job or industry. Industries need solutions that are designed to ensure high energy efficiency and performance, at the same time keeping up with the pace they work; this is where twin lobe rotary air blower comes in. This equipment moves materials faster and saves times when it comes to finishing an important work.

Wastewater treatment is an essential line of defence as it involves removing pollutants from water so that the cleaned water can be used for different purposes. In this process, the twin lobe root'sm rotary air blowers are playing a crucial role. They actually help to oxygenate the water, so they bring air in the water. This aeration is necessary because without oxygen in the water, it allows little organisms called microorganisms to collapse the dangerous compounds.

There are numerous advantages to using twin lobe rotary air blowers in the wastewater treatment process, including: Consequently, the machines can actually help lower energy costs along with increased efficiency and purer water. Improves the treatment by fasten up processing make sure water is treated faster without compromising on safety.

Every employee, from director to worker are service providers that offer highest quality and professional services. Products undergo strict standardized monitoring before they leave factory. If there is any issues with product's quality, is replaced within one year. Within 24 twin lobe rotary air blower, video assistance is available for debugging and team can visit the project's website find any issues with the product within a matter of 48 hours.

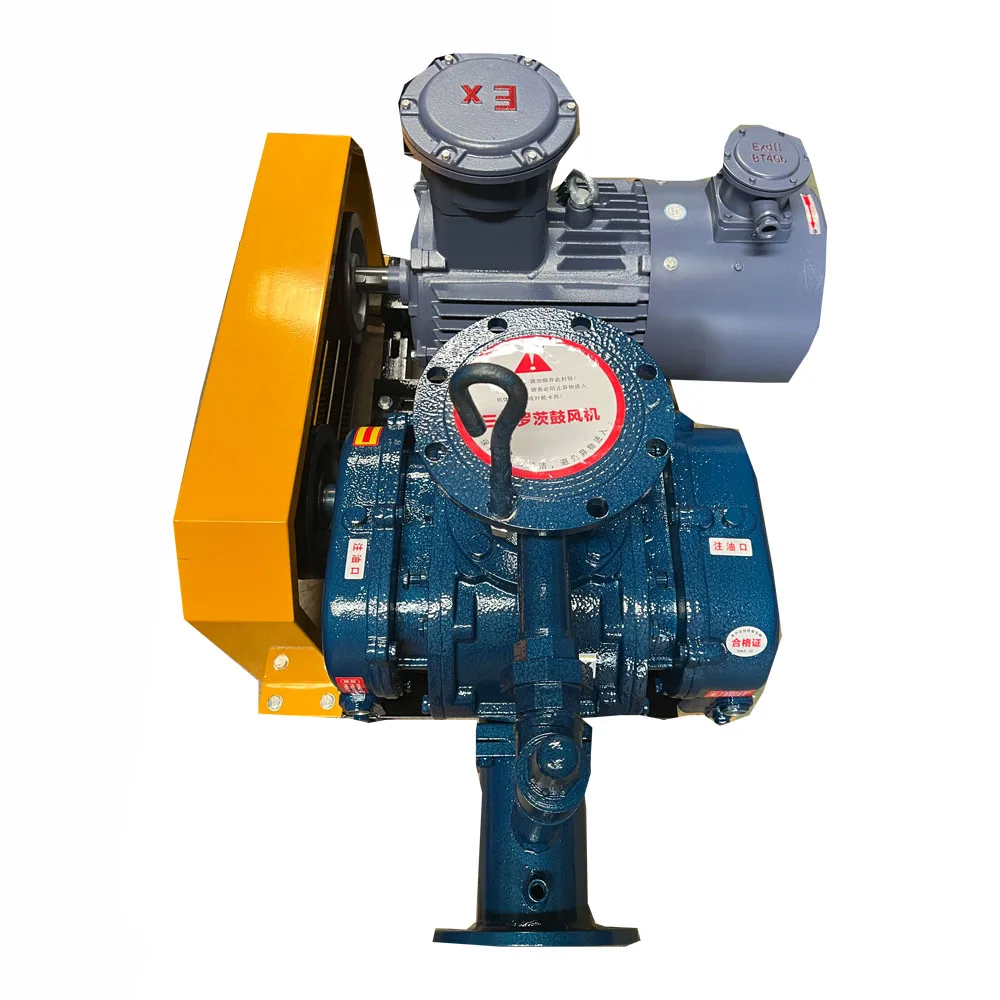

Three-blade Roots Blower is quieter has less vibration as compared to 2-blade Roots Blower. castings are cast with resin sand technology and impeller is constructed following the involute theory simulated by a computer. maximizes the meshing features of involute as well as increases efficiency. ports for exhaust and twin lobe rotary air blowerare arranged in a spiral and come with muffler. This ensures that intake and exhaust vibrations are soft as well as the vibrations low and the noise low. fan gear is made from 20CrmnTi that has been carburized then ground to a level of 5 accuracy. surface of the tooth more wear-resistant and can substantially reduce the sound of the gear.

Shandong Jianyu Heavy Industry Co., Ltd. Blowers, Roots twin lobe rotary air blowerused in various industries, including melt-blown fabric well as aquaculture and sewage treatment, pneumatic transport, special gases and dust removal along petrochemicals and power cement. Roots blowers are manufactured in the US and manufactured and provide problem of strong. company is a leader in technical production development capabilities. It is company that combines development, research, manufacturing and sales. company's leading product, three-blade Roots blower is optimized designed absorbing both domestic as well as foreign Roots blower experience in design. There over ten models, and more than 100 specifications. It is easy to operate, compact but has a significant flow rate, and is low-noise. Smooth, virtually no noise in whole machine

(1)More efficientTransmission lubrication system coordination structure are distinct can reduce losses.(2)Longer life primary twin lobe rotary air blowerimported, and unique design of lubrication system helps the fan function easily, safely efficiently with a low rate of failure longer run time.(3) energy efficiency and protection of the environmentThe design of the unique sealing system makes the output air cleaner. The structure's patented noise reduction design makes the equipment less noisy and also reduces energy consumption.

Copyright © Shandong Jianyu Heavy Industry Co., Ltd. All Rights Reserved | Blog | Privacy Policy