JYSR

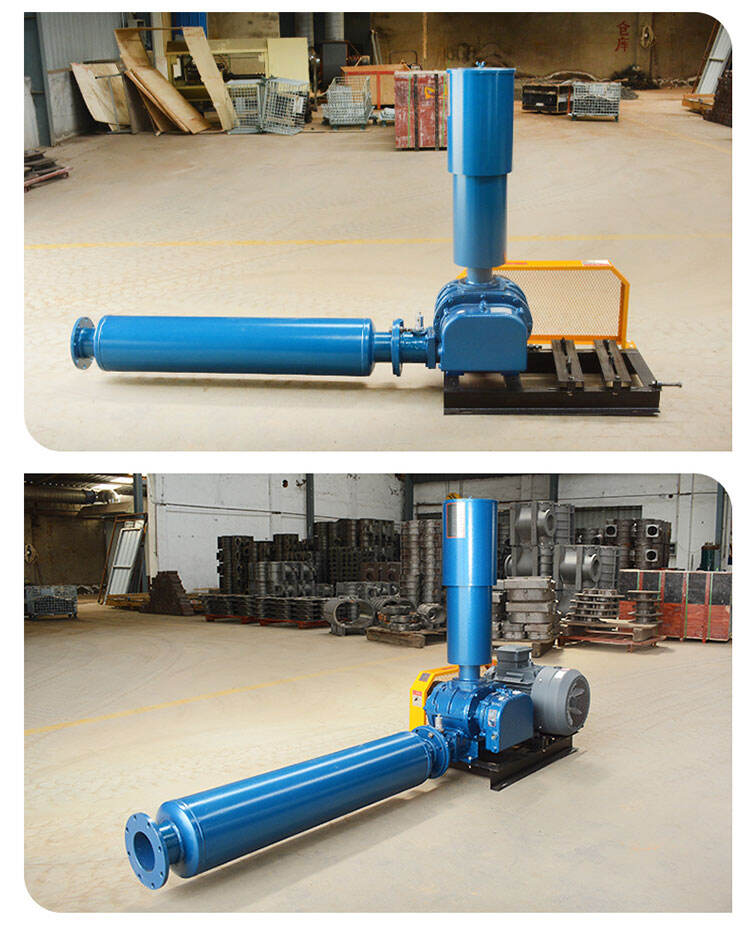

The Pneumatic conveying of three blade Roots blower boiler exhaust gas emissions is developed to effectively manage and transport the exhaust fuel emissions of the boiler using a three blade Roots blower. This technique is perfect for industries that require the safe and managing clean of emissions for environmental and protective purposes.

The Pneumatic conveying of three blade Roots blower boiler exhaust gas emissions works by making use of compressed air to go the hot and potentially dangerous gases through the boiler to a safe location for launch to the atmosphere. The JYSR 3 blade Roots blower is a component is vital this action, since it ensures a flow smooth of through the boiler to the conveying system. The machine was made to efficiently handle the number of gas created by the boiler and steer clear of any blockages along the way.

The JYSR Pneumatic conveying of three blade Roots blower boiler exhaust gas emissions is a solution is cost-effective companies that need to deal with their air pollution issues. The system has a dirt control device, which filters the fuel emissions, making sure these are generally safe when it comes to surroundings. The Pneumatic conveying of three blade Roots blower boiler exhaust gas emissions minimizes the importance of manual handling related to the emissions, consequently reducing the risk of accidents and injuries at work.

Utilizing the JYSR Pneumatic conveying of three blade Roots blower boiler exhaust gas emissions ensure that their fuel emissions are handled safely along with conformity with environmental regulations. The machine is easy to set up and therefore could be modified to complement the initial requirements of every industry. JYSR’s experienced group of experts can offer expert advice on the installation, maintenance, and operation regarding the system to be sure performance is optimal.

The Pneumatic conveying of three blade Roots blower boiler exhaust gas emissions can be energy-efficient, as it uses compressed air in the place of electricity to maneuver fuel emissions. This reduces the carbon impact associated with industry and fundamentally decreases its effect on the environment. The device normally built to be low-maintenance, therefore, decreasing the entire expenses of procedure and ownership.

Roots Blower Production Process

A:Machine Casing Machining Component

Machine Blank-production&testing - Rough milling - Finish milling - Bore hole -drilling&tapping -Testing -Stock

B:Lobes Machining Component:

Machine Blank-Production&Testing-Lathe Facing&reaming hole-rough plane-finish plane-

semi finished products -shaft installation-make static&dynamic balance

C:Drive/Driven Shafts Machining Component:

Steel rod testing -cutting -Heat treatment -Bore Holes-Lathing smoothing-install shaft into the lobes-testing-stock.

D: Wall Plate Machining Component:

Plate Blank production - plate wall milling - bore holes -testing -stock

Shandong Jianyu Machinery Co.,ltd is situated in the famous town of mechanical processing Xianggong town, Zhangqiu district, Jinan City, Shandong Province. We are always specializing in researching and manufacturing roots blower and roots vacuum pump, we have got many honors and much reputation home and abroad.

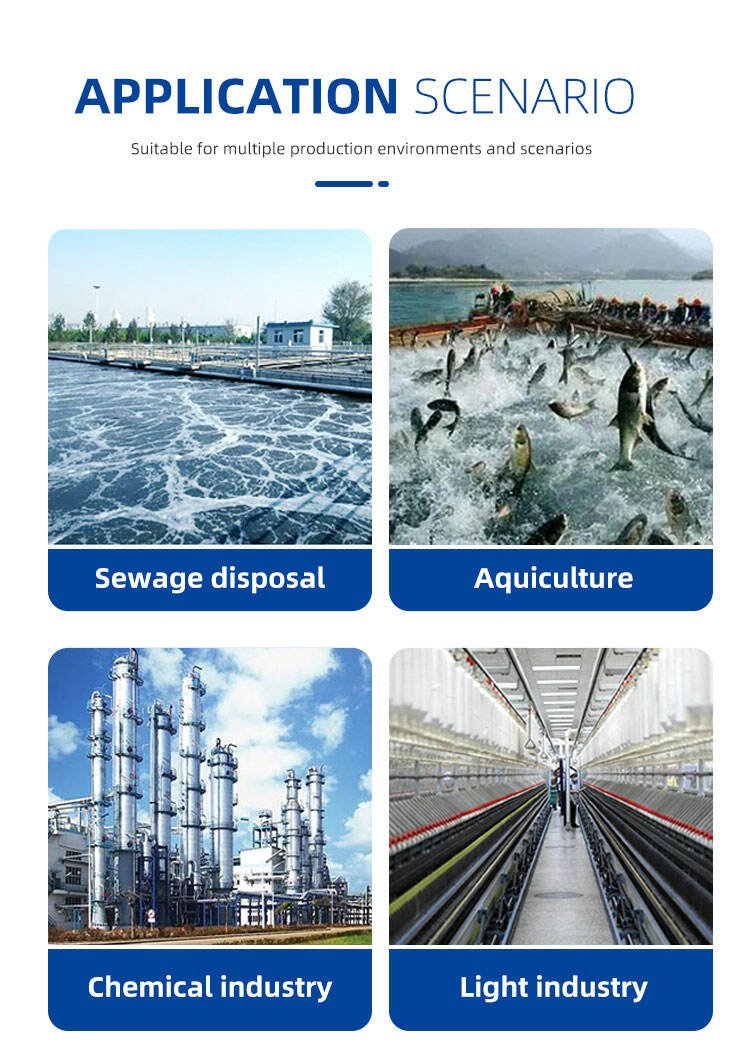

We have RSR/MTS/MTRR/MTRG/MTRH/MTRF/MJSR series roots blower, roots vacuum pumps and the related products, which is widely used in sewage treatment, chemical plant, MVR project, cement plant, electric power plant, fertilizer plant, paper producing, coal mill, textile mill, food plant, aquaculture, vacuum package, metallurgy industry and many other industrial.

Adhering to the guideline of “Specialty builds quality, honesty creates future”, we have establishes perfect system of before and after sales service, lifelong free technical consulting support, we are willing to cooperate with friends from all over the world to create a long time booming business.

Payment terms,Packaging and Shipping

A. Our payment terms is mainly choice T/T,L/C or other terms you are convenient.

B. Our package including two methods: standard exported wooden box and iron box.

C. Our transportation: by sea, air or railway transportation.

1.Shandong Jianyu had passed ISO9001 management system certificate in 2007.

2.All of our roots blower model products had passed CE certificate for European Standard.

3.Shandong Jianyu 's roots blower all have following own patent including:

(1).A Roots blower case with low noise

(2).A composite wire rotor of three-lobe Roots blower

(3).A high negative pressure Roots vacuum pump

(4).Vacuum pump case(high negative pressure)

(5).A high pressure air-cooling Roots blower

(6).A photoelectric dividing apparatus of three-lobe rotor

(7).Back flow pressure relief valve

(8).Roots blower(high pressure air-cooling)

(9).A Roots blower with cooling tank without leakage

(10).A Roots steam compressor

(11).A Roots steam compressor

(12).A steam compressor with mechanical seal

(13).A mechanical-sealed steam compressor’s circulating water system for cooling

(14).A steam compressor’s wallboard

(15).Intelligent monitoring system of Roots blower

FAQ

Q1: How about the price?

A: The price is negotiable. It can be changed according to your quantity or packaging.When you are making an inquiry, please let us know the quantity you want.

Q2: How about the after-sales service?

A: We provide 1 year's guarantee, installation guide, and life-long free technical consulting.

Q3: How about the OEM?

A: Welcome, you can send your own design of blower product and LOGO, we can open new mold and print or emboss any LOGO for you.

For more detailed information , hope you could finish below form or click "chat now" for online service on the right side.